The MEPROTEC HFSmart is the most advanced solution to optimize hot forming processes. It is based on in-depth metallurgical know-how combined with newest software technologies to simulate the entire production process. Its key features are:

Software Features

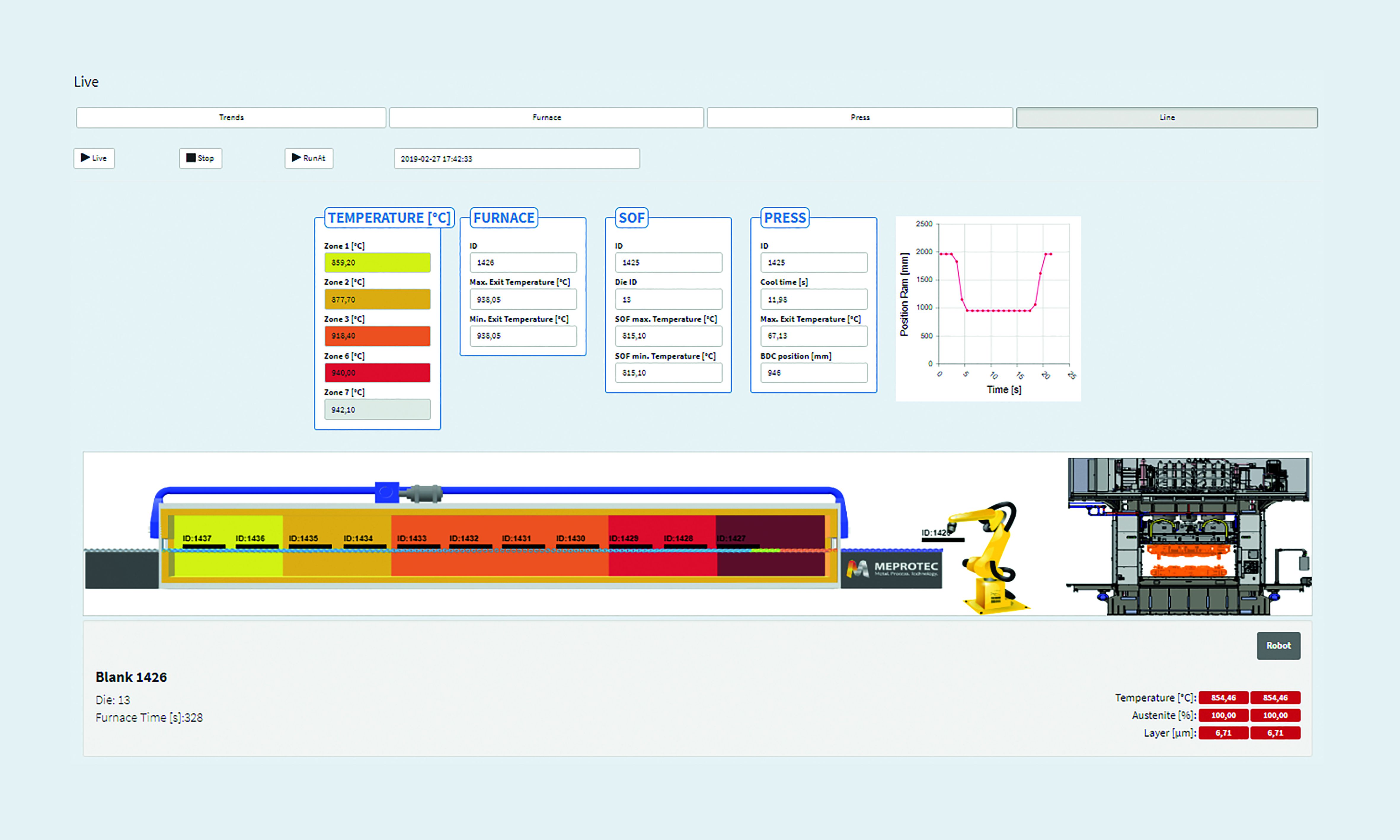

Visualize. Control. Optimize.

The MEPROTEC HFSmart is your handy partner all along your hot forming challenges. It helps you to visualize, control and optimize your processes on a real-time basis. It is based on the in-depth know how of our metallurgical experts and guides you on an easy basis to more efficient processes with consistent production quality.

Efficient Process Management.

Focus on production and quality

Live calculation of product properties

Easy failure analysis

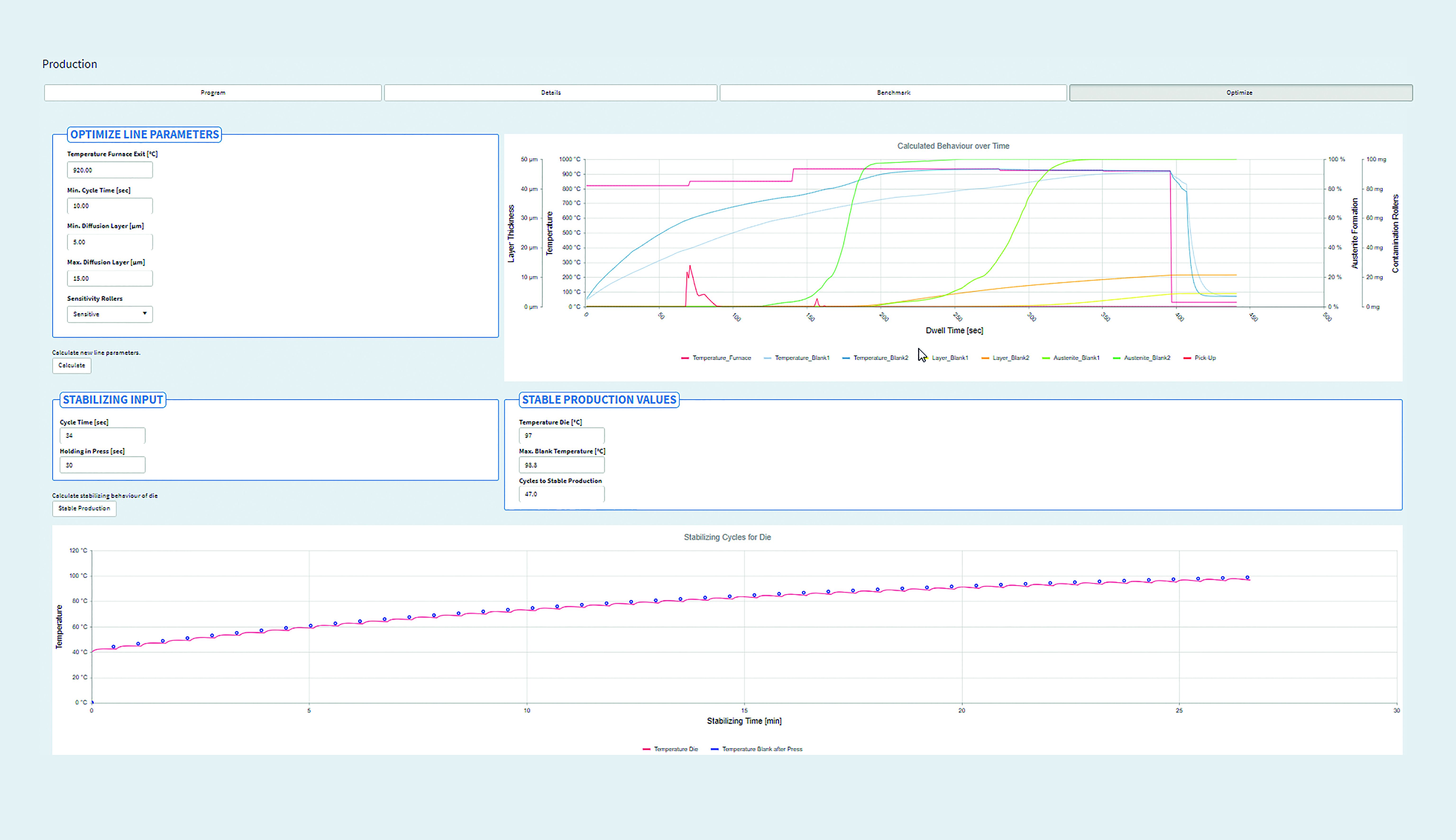

Automated Calculations.

Diffusion in coatings

Patched and TRB blanks

Austenitization

Temperature calculations for product and line components

Tailored Tempering

Reduce Consumption.

Reduce roller contamination

Reduce energy consumption

Optimize Throughput

Reduce scrap

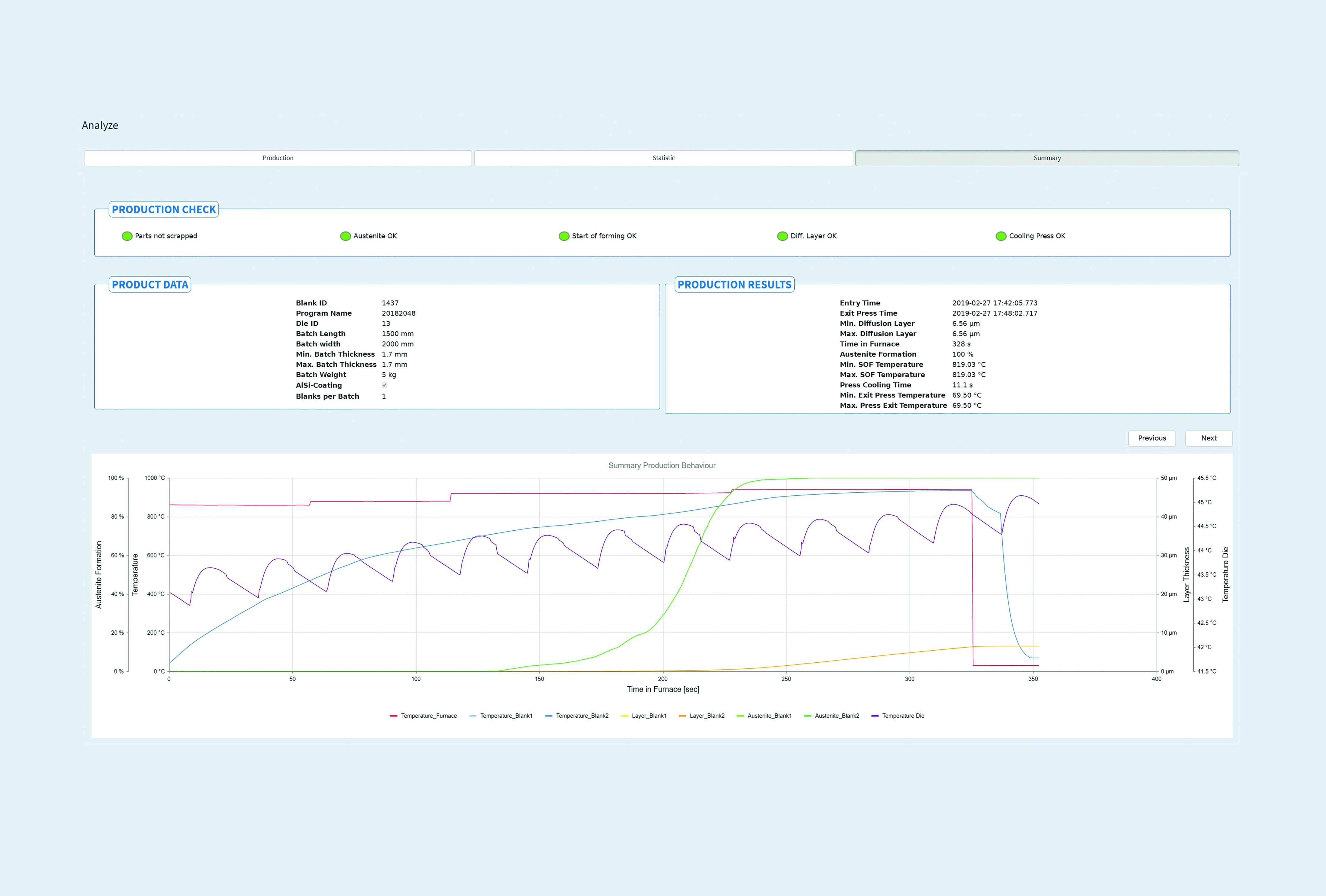

Full Traceability.

100% requirements traceability of single blank

Trends of complete production history

Data archive of each single blank

Added Value

Higher Productivity

Simply adjust your process parameters to raise troughput and OEE.

Full

Traceability

Professional data archiving for requirements traceability of up to 100%.

Full

Visualization

Enhanced visualization and reporting of thermal process steps and material characteristics.

Perfect

Quality

Reproducible production conditions due to online process optimization.

Reduced

Energy

Reduce gas and electric energy consumptions with optimized temperature settings.

No more

Trials

We help you to meet requirements from the start.

Flexible

Access

Connect with PC, tablet, smartphone from all over the world.

Lower Roller Contamination

Lower roller consumption and less drift of blanks due to reduced build-ups.

Full

Control

Gain full control over your processes.